Gramazio and Kohler is a research group based in ETH Zurich, Switzerland, who consider the “interlinking of data and material and the resulting implications for architectural design” [gramaziokohler.arch.ethz.ch]. Working between material, manufacturing logic, and the design process, the group uses technology, robots, and programming as a means to define a new architectural expression.

Interrogating methods and workspace limitations of the construction/build process, Remote Material Deposition literally builds from afar; “remote material”, as in material situated at a distance, and “deposition” as the ejection, depositing, and/or build up of a material.

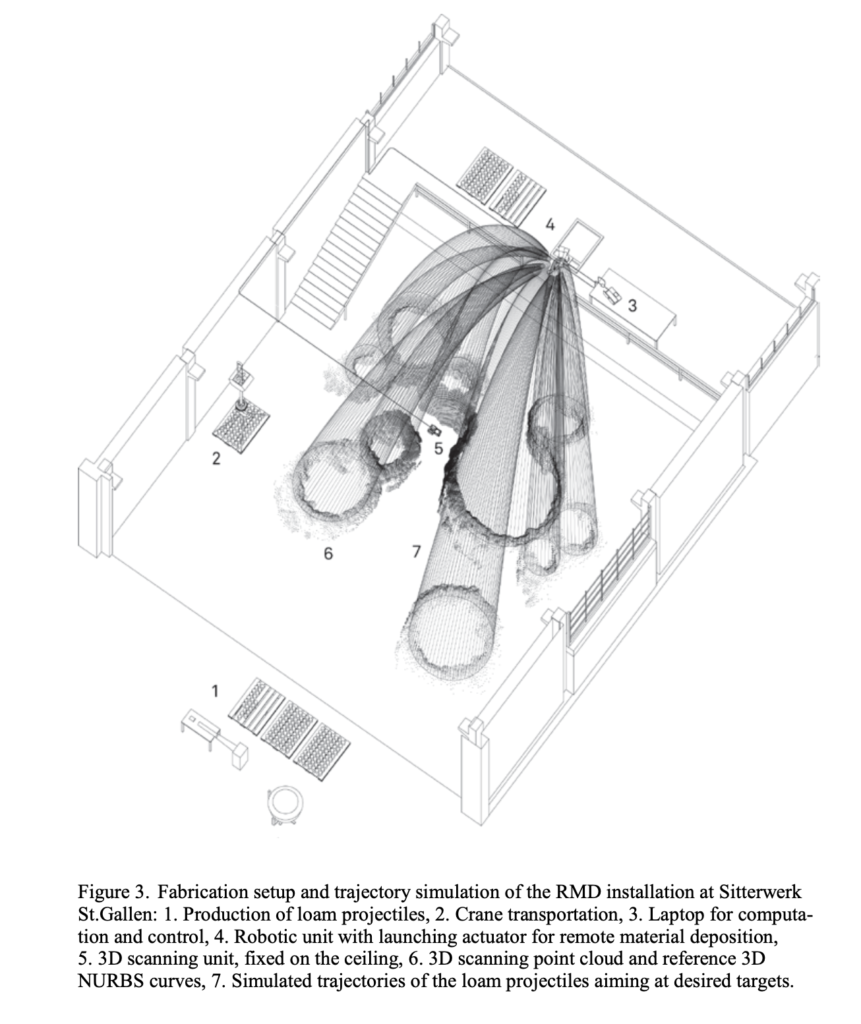

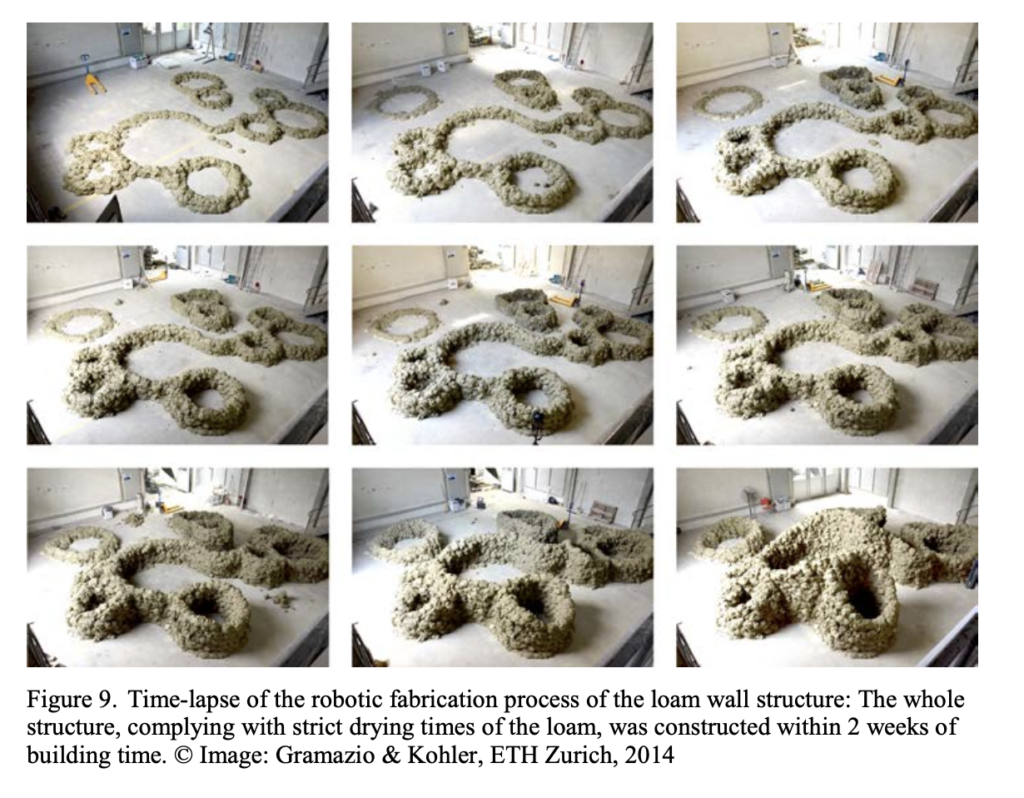

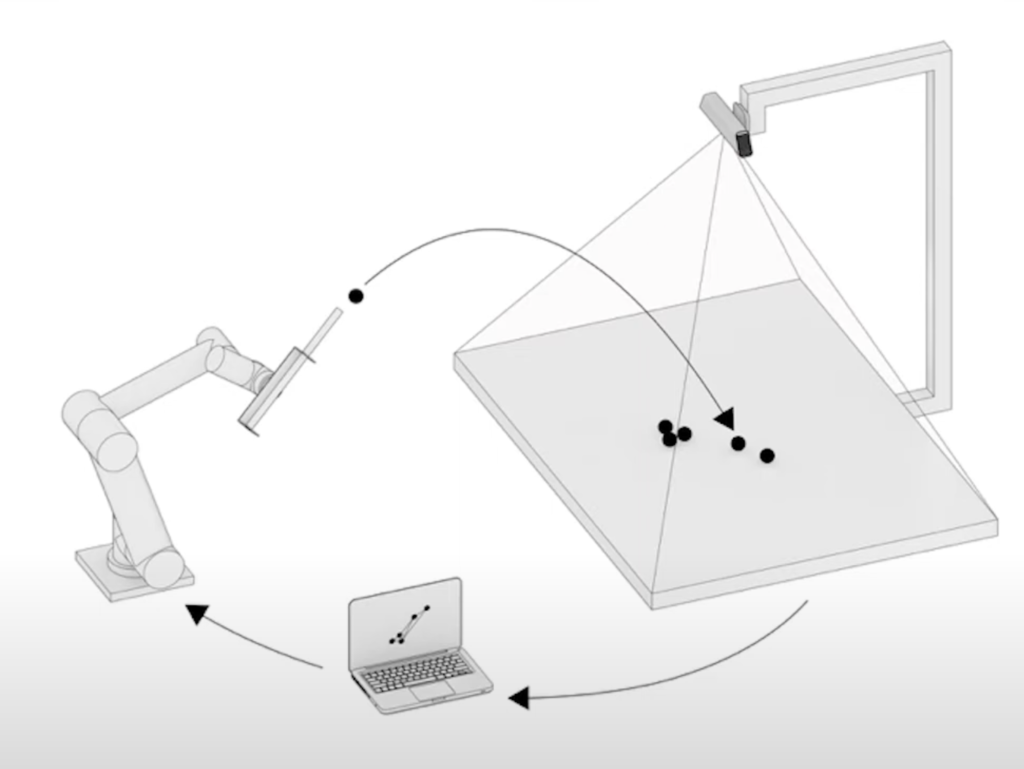

A robotic catapulting device, which is hooked up to a camera sensor installed at a birds-eye view, is installed within in a confined workspace. The catapulting device is loaded with loam projectiles, a composite soil made of clay, sand, and silt. The material in this process must be able to adhere to its fellow material upon impact, and harden after. For this reason loam (mud, earth) was chosen as the primary building material. The loam is shaped in cylinders, as to maximize the colliding forces of impact in order to adhere to the existing materials that were “shot” before it. Below is a diagram of the workspace.

Since uncertainties are bound to occur with the depositing, or lack of depositing, of the loam projectiles the over head sensor captures the mistakes, uncertainty, and data from the build, sends that information back to the design system (computer), and adjusts for the next round of projectiles. Although a defined proposal for design is used to set up and initialize the machine, the construction and build process becomes the design process; the two are linked in a feedback loop.

The use of earth/loam in this context is necessary for the method of construction applied, the adherence of projectiles, however the material and concept of this application can exist independently. What would the process of “ballistic architecture” look like at a much larger scale, if material were not a condition?

Consider the word “ballistics”: missiles, bombs, destruction. Countries such as Palestine and Afghanistan (and so many more) have had entire historical and cultural identities destroyed through ballistic warfare and destruction of their architecture and built infrastructure. It is an incredible thought to place Gramazio and Kohler’s work in the context of ballistic creation. Instead of destroying each other through missiles and projectiles, can countries and nations build each other instead?

Size: 12 m × 12 m and a ceiling height of 7 m (interior construction space)

Year: 2014

Photos: ETH Zurich, Gramazio and Kohler, Michael Lyrenmann

Architects: Gramazio and Kohler

Students: unknown

References:

[1] https://gramaziokohler.arch.ethz.ch/web/e/lehre/277.html Gramazio Kohler website

[2] https://www.researchgate.net/publication/317340911_REMOTE_MATERIAL_DEPOSITION Conference Paper

[3] https://vimeo.com/100784860 Production video