Image Source: Munarq

Image Source: Munarq

Project Start : 2021

Project End : 2024

Location : Binissalem, Mallorca, Spain.

Team : Munarq Architects

Gross Floor Area: 300 m²

Ca na Pua is a sustainable earthen home built in Binissalem, Mallorca; an island off the shore of Spain’s Mediterranean Sea. Ca na Pua was designed by munarq, an architectural studio based in Mallorca founded by Rafel Munar and Pau Munar focused on the integration of architecture in the Mediterranean landscape. inclusion of the environment

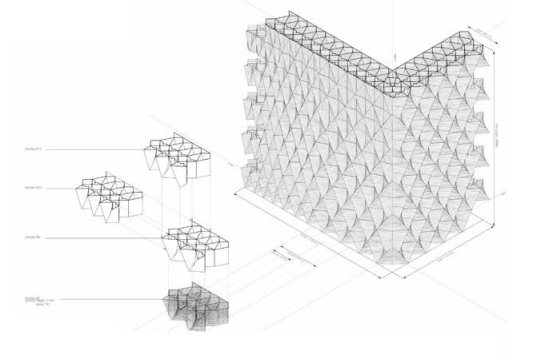

To construct this house munarq used an old local Mallorcan technique known as ballast. During this process, aggregates of various sizes, stone, and lime are mixed together to create a strong base. Then an open diffusion membrane between two ballast to allow for waterproofing. Waterproofing supports the overall longevity of the building while maintaining a healthy indoor environment.

The interior of the house uses a coat of earth and lime that creates hygrothermal environment environment. The earth-lime mixture acts as a natural buffer, absorbing and releasing moisture to maintain a comfortable and stable indoor climate.

The roof is insulated using straw coverage laced between laminated wood beams. This setup creates a dense and well-integrated insulation layer that provides thermal resistance.

There is an interaction with the built environment with the build patio or oasis shared within the home.