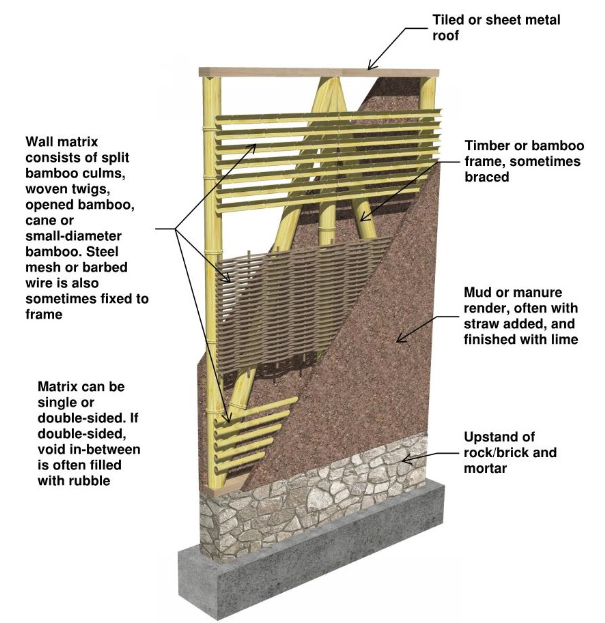

Bahareque is the Spanish name for what is known in English as wattle and daub, a method of building where wet loam is applied to an interwoven mesh of twigs, branches, bamboo, etc. Specifically, bahareque (also known as quincha) is a subset of the thrown loam technique, where the wet loam is applied by hand onto the organic skeleton. The loam of earth (a combination of clay, silt, and soil) and aggregate, usually straw. Bahareque describes a wide range of building techniques and types, and can be separated out into various local traditions across South America.

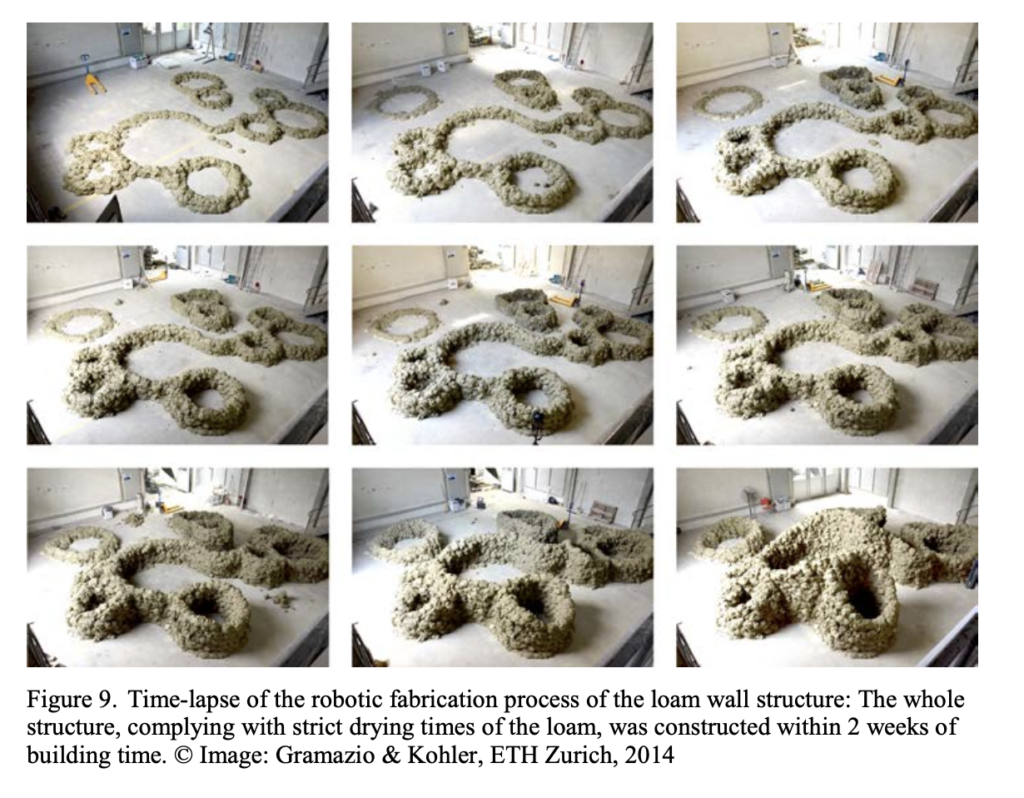

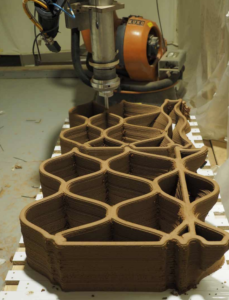

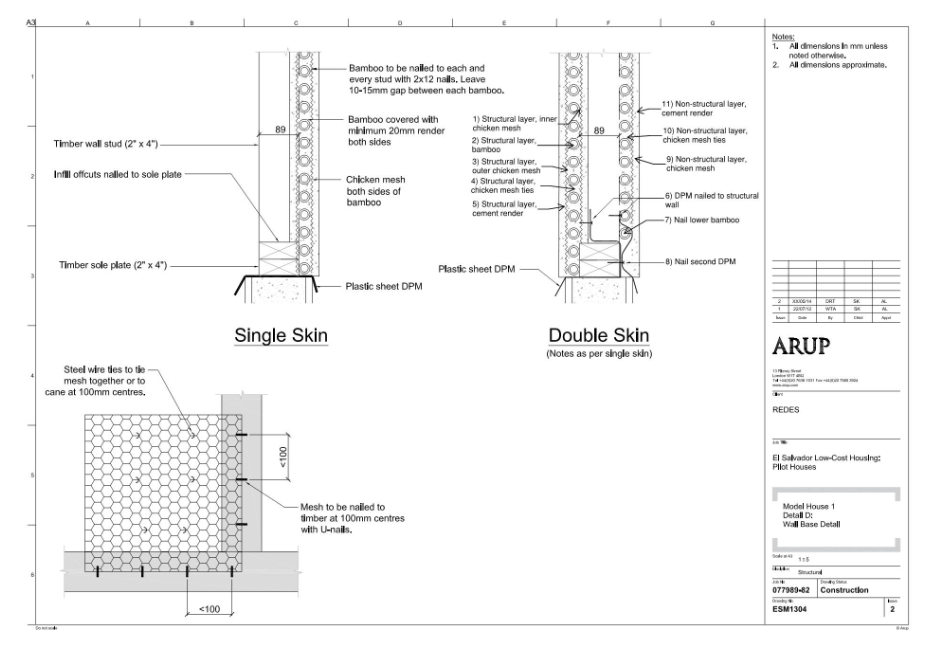

Originally combined with palm frond roofs, bahareque was often topped with tiled roofs after European colonization. It can be used in combination with other earthen architecture technologies, as seen in the image below.

Bahareque is currently being explored as a low-cost housing typology. There are questions as to how well it can withstand seismic activity, but it is often proposed as a housing solution for earthquake stricken regions. Costa Rica, Ecuador, and Brazil have all introduced engineered bahareque (or cement bahareque) following devastating earthquakes.

In Ecuador, where the matrix and frame for bahareque architecture is made of guadua bamboo, one of the strongest bamboo subspecies, there is promising contemporary research proving that bahareque is superior to masonry architecture both for earthquake safety and from a sustainability standpoint.

References:

[1] http://www.crockerltd.net/adobe_big_one.htm

[2] https://www.seismico.org/bahareque

[3] https://www.researchgate.net/publication/282701710_Engineered_bamboo_houses_for_low-income_communities_in_Latin_America

[4] https://www.researchgate.net/publication/311583390_Design_Guide_for_Engineered_Bahareque_Housing/download