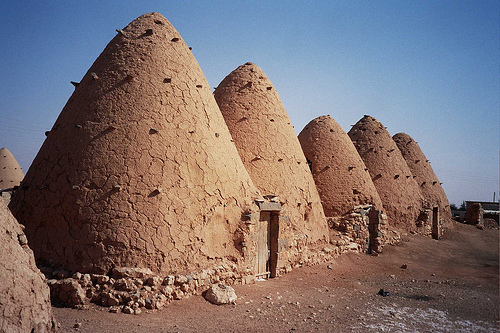

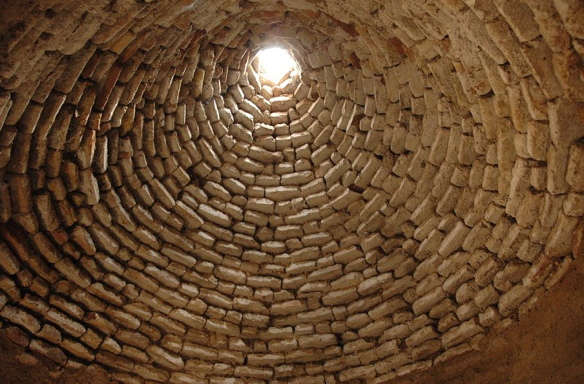

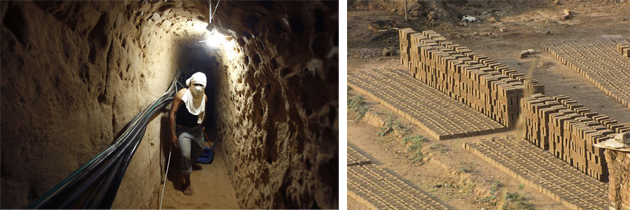

Previously we reported that the Israeli siege on Gaza led to citizens constructing their houses with mud brick due to a lock on billions of dollars in reconstruction funds pledged by the international community. The ingenuity also stems from a resource created by the excavation of border tunnels, primarily in the Rafah region, used to transport goods from Egypt. When tunnels are dug, mounds of mud are created, and this mud is considered prime for the production of mud bricks. Under the siege, and due to Gazans’ loss of hope that reconstruction projects will rebuild the thousands of houses and institutions destroyed by the Israeli occupation, particularly during its New Year offensive, many homeowners have begun to explore the mud alternative.

Photo credit (left), Photo credit (right)

“Hamas is actually supporting the mud-brick housing movement and has pledged money and assembled a special engineering committee to investigate a pilot project that will test a multistory school to determine just how safe and plausible building more widespread with mud brick can be. Of course, all of this has spawned a new temporary economy in tunnel mud removal and brick manufacturing, and the engineering itself is quite antiquated but none the more outdated. They’re using combinations of mud, sand, salt, and straw, and in some cases rubble to forge bricks and build basic homes. Some have already been said to have withstood elements of winter rains and harsh summer sun….It’s almost as if the tunnels had been turned inside out, sort of poetically unraveled overland as a result of the Israeli assaults, and now offer the dual benefit of both relief housing while also keeping the essential corridors of underground commerce alive. In some ways it’s just good old-fashioned poetic justice bound with some gritty irony. “ writes Subtopia.

Several videos about the mud brick houses are available on YouTube. In one, the daughter of Nidal Eid, a 35 year-old who constructed his own mud brick house, states, “Daddy makes everything out of mud, but he can’t make me mud toys.” In another video it is suggested that building with mud brick is “a step back in time.” But is it a step back, or a step forward, creating a Palestinian identity through architecture drawn from tunnels that “represent the frontier of Gaza’s fight for geo-economic autonomy…amazing blueprints as uprooted spaces edited into fresh new infrastructure now in plain view”, as mentioned in the Subtopia essay. “Mud is valuable”, mentions a builder of a mud brick house in another video.

[Gaza’s Mud Brick Homes | Gaza’s Gritty Mixture of Dirt, Despair Produces Houses of Mud | Mud, mud, glorious mud. Nothing quite like it for beating the Israeli blockade | Subtopia: Over the Siege ]