Haydar Yaghma, a humble yet prolific Iranian Poet, carved his legacy not only in verse but in the earth itself. Born into a life of labor, Yaghma spent his days shaping adobe bricks—a traditional craft in Iran’s sunbaked landscapes—while his nights were filled with the spirit of words and ideas. Despite his profession, Yaghma’s poetic talent soared; he composed over 5,000 verses that speak to the beauty of simplicity, the resilience of the working class, and the profound connection between humanity and the land. His verses, grounded in the experiences of everyday life, offer readers a raw and unfiltered view into the soul of a man who, though seemingly bound to the soil, found liberation in poetry. Haydar Yaghma remains an emblem of authenticity and passion in Persian literature, bridging the gap between the hands that labor and the mind that dreams.

Christine Howard Sandoval

Who is Christine Howard Sandoval?

Sandoval is an interdisciplinary artist working across media including sculpture, installation, performance, and public art. Her versatile practice allows her to express her conceptual interests through a variety of artistic forms.

Sandoval is currently an Assistant Professor of Interdisciplinary Praxis in the Audain Faculty of Art at Emily Carr University (Vancouver, BC). Howard Sandoval is an enrolled member of the Chalon Nation in Bakersfield, CA. As an artist and writer engaging with timely ecological and social justice issues, Sandoval’s practice is situated within important contemporary conversations around environmentalism, indigeneity, and cultural representation.

https://www.brokenboxespodcast.com/podcast/christine-toward-sandoval

https://www.brokenboxespodcast.com/podcast/christine-toward-sandoval

Cultural Identity and Influences:

As someone of Mexican and European American descent, Sandoval’s multifaceted cultural heritage is a core influence on her artistic vision and the themes she explores.

Her work often engages with questions of land, place, and indigenous environmental knowledge, reflecting her connection to the American Southwest region where she is based.

This cultural hybridity and commitment to representing marginalized perspectives is a key aspect of Sandoval’s artistic identity.

Education and Career:

Sandoval has formal training in the arts, holding a BFA from the University of New Mexico and an MFA from UC Davis.

Her educational background has provided her with a strong technical foundation to realize her conceptual ideas across different mediums.

Over the course of her career, Sandoval has exhibited her work internationally and received prestigious awards and grants, indicating her recognition within the contemporary art world. Howard Sandoval has been awarded numerous residencies including: UBC Okanagan, Indigenous Art Intensive program (Kelowna, BC), ICA San Diego (Encinitas, CA), Santa Fe Art Institute (Santa Fe, NM), Triangle Arts Association (New York, NY).

Examples of her work:

-Coming Home, August 21 – October 31, 2021

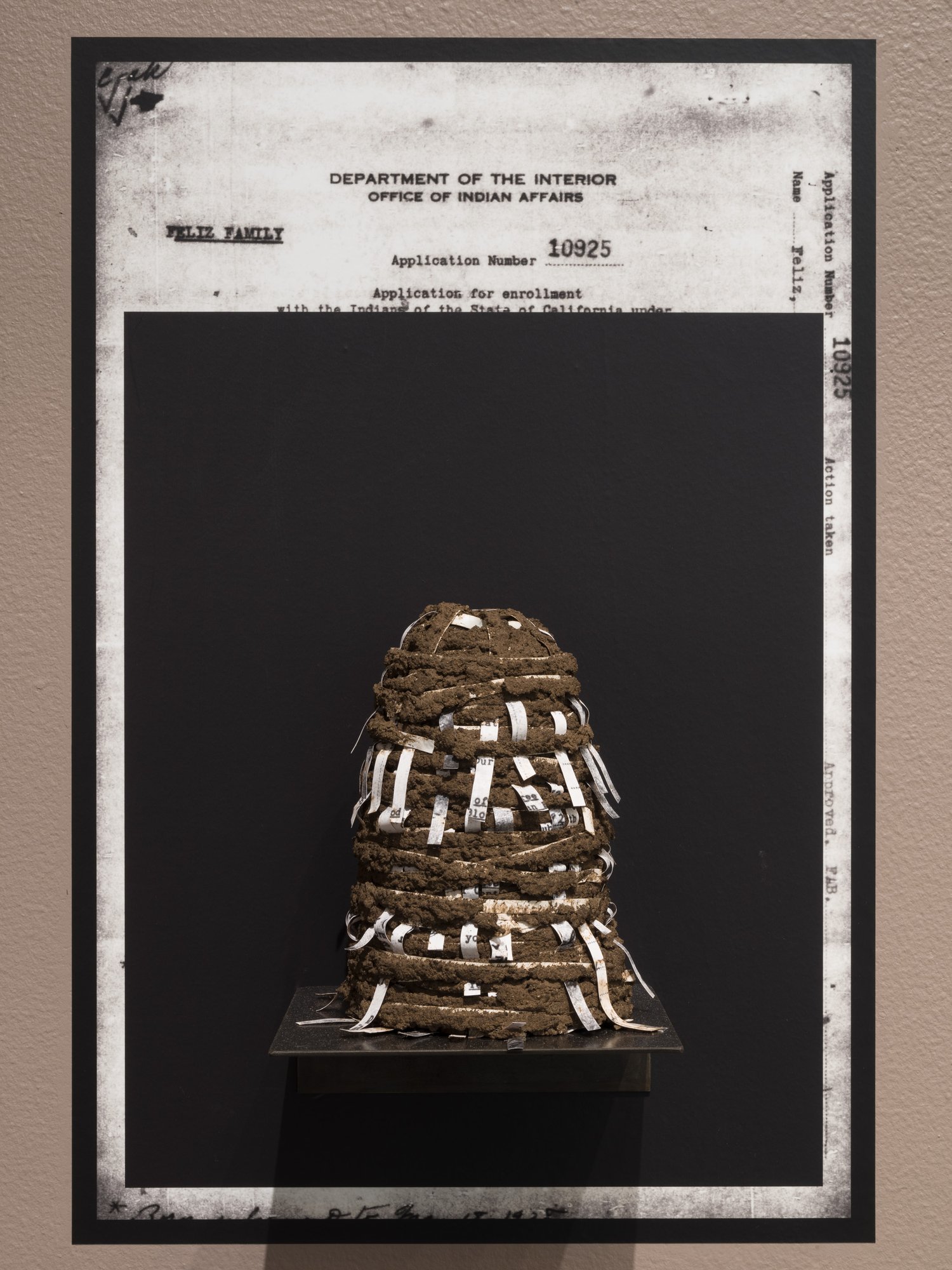

“In Coming Home Christine Howard Sandoval explores the history of California Indigeneity and its relationship to the archive, a place in which collective memory is stored. In California, the documentation constructed by settlers embodies a narrative of erasure but is also embedded with the seeds of Indigenous knowledge paramount to the reconstruction of Indigenous language, cultural practices, and relationships to the land. Howard Sandoval works with the archive to trace the migration of her Chalon Ohlone ancestors, telling the story of her community, her family, and her coming home to California.”

Document Mounds- Application for Enrollment with the Indians of the State of California Under The Act of May 28, 1928 (6 pages), 2021, inkjet print on vinyl, tape, adobe mud, and steel, 24H X 16W X 7D inches each.

Document Mounds- Application for Enrollment with the Indians of the State of California Under The Act of May 28, 1928 (6 pages), 2021, inkjet print on vinyl, tape, adobe mud, and steel, 24H X 16W X 7D inches each.

Surveillance Mound, 2021, adobe mud, tape, steel, wood, wire, paint, 89.5H X 19W X 19D inches.

Surveillance Mound, 2021, adobe mud, tape, steel, wood, wire, paint, 89.5H X 19W X 19D inches.

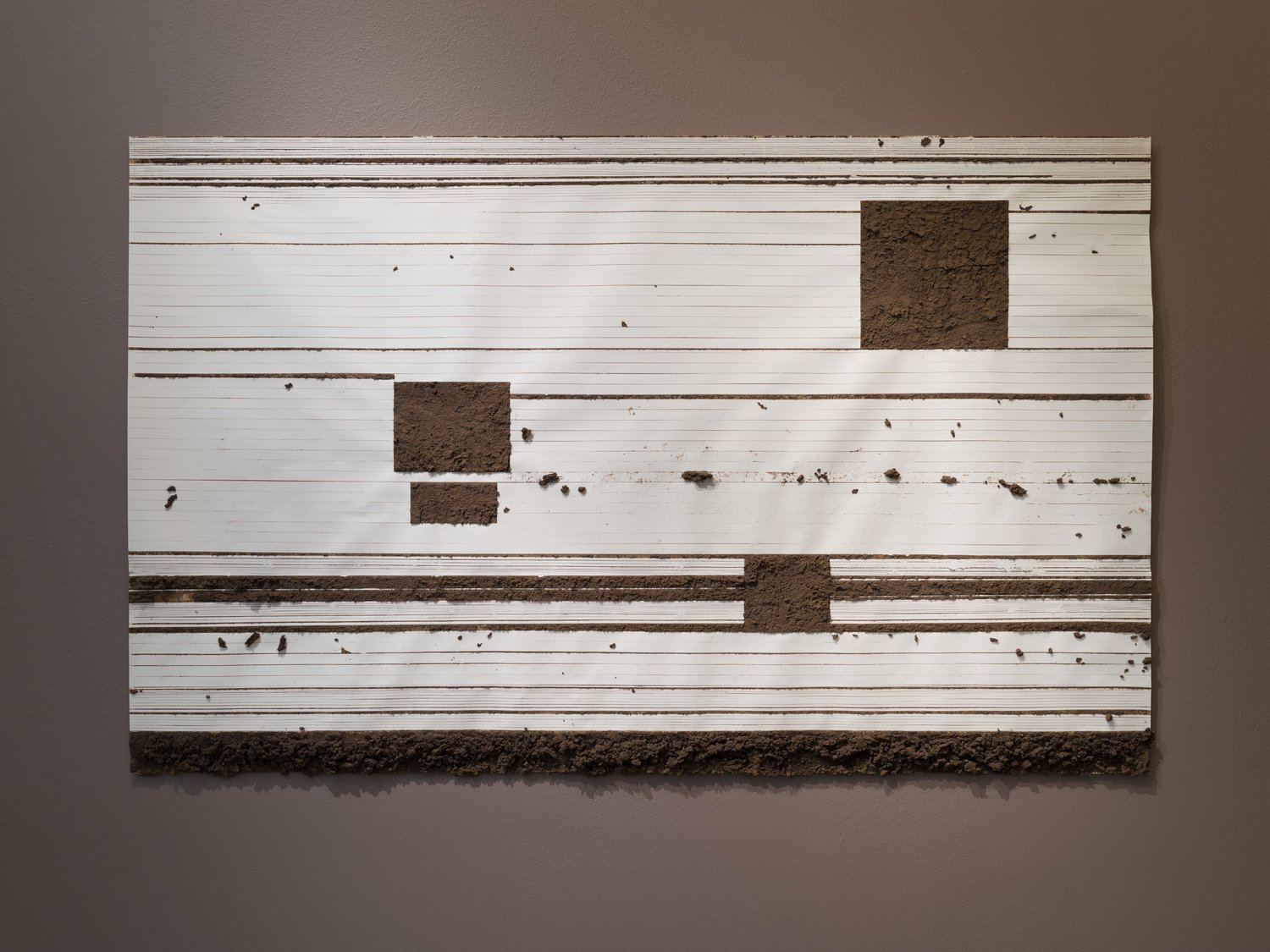

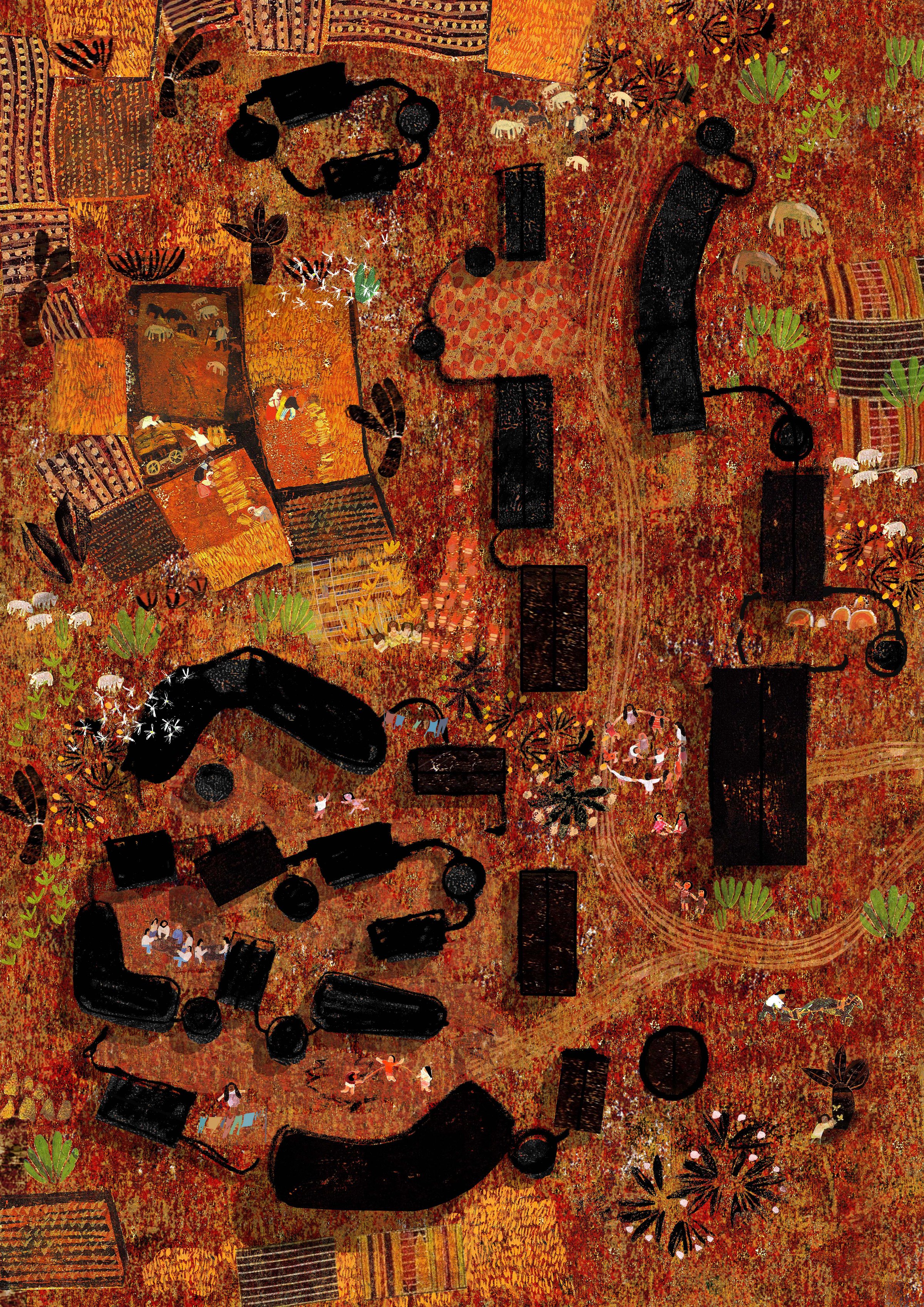

Sending Signals Into The Ground To Form Images Of What Is There To See, 2020, adobe mud on paper, 60 X 96 inches.

Sending Signals Into The Ground To Form Images Of What Is There To See, 2020, adobe mud on paper, 60 X 96 inches.

-The green shoot that cracks the rock, May 27 – July 16, 2022

“Howard Sandoval’s embodied work confronts the complex history and innate interconnection of land and body. As she traces a path to her ancestral home, the artist scrutinizes the narrative of erasure in early North American settler’s records and reassigns power through documentation of embedded Indigenous cultural practices. Her poetic oeuvre seeks to weave a collective awareness back to nature by means of a more cyclical and deepened relationship with land and place.

The land, as an ever-evolving being, plays a central role in Howard Sandoval’s visual language. Taking adobe as her main medium, the artist explores its inherent properties of historical, familial and ecological histories. Adobe mud requires a bodily process to mix soil (sand, silt and clay), water and often straw to form a workable, malleable and ultimately structural material. In this ongoing investigation, she emphasizes the intentionally omitted history of forced labor, land theft, and the violent genocidal actions Indigenous people experienced.”

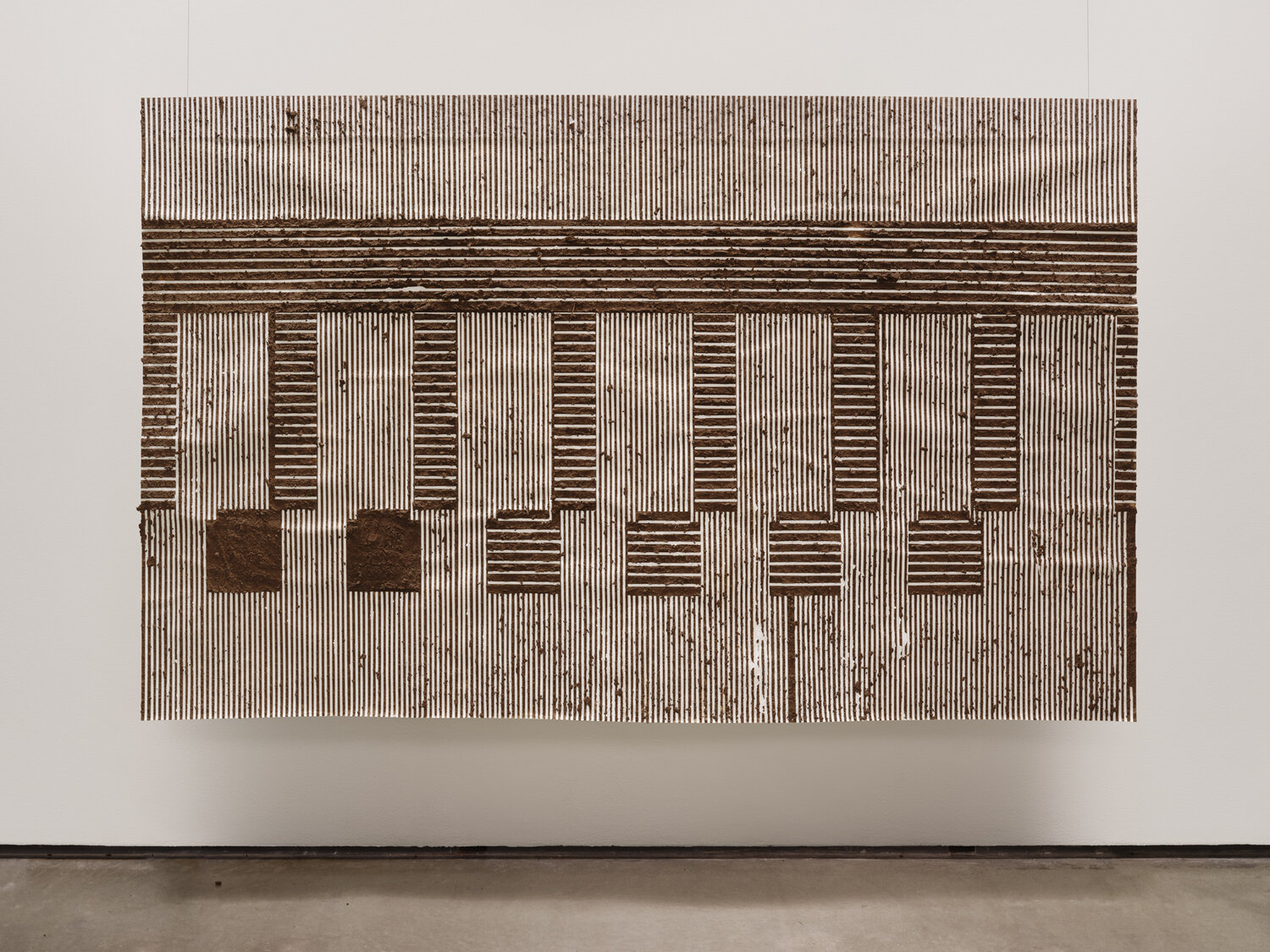

Installation view, the green shoot that cracks the rock, parrasch heijnen gallery, LA, 2022

Installation view, the green shoot that cracks the rock, parrasch heijnen gallery, LA, 2022

Niniwas- to belong here, 2022, single channel video with audio, TRT 12:23, Sound design in collaboration with Luz Fleming

Installation for the green shoot that cracks the rock, parrasch heijnen gallery, LA, 2022

Stretcher- For The Transportation of Water, 2021 adobe mud, tape, steel, wood, wire 54 x 56 x 27-1/4 inches

Stretcher- For The Transportation of Water, 2021 adobe mud, tape, steel, wood, wire 54 x 56 x 27-1/4 inches

Mound- Angle of Integration, 2020, adobe mud and graphite on paper, 60 X 96 inches.

Mound- Angle of Integration, 2020, adobe mud and graphite on paper, 60 X 96 inches.

Pillars- An Act of Decompression, 2020, adobe mud and graphite on paper, 60 X 96 inches.

Pillars- An Act of Decompression, 2020, adobe mud and graphite on paper, 60 X 96 inches.

Arch- A Passage Formed By A Curve (detail), 2020. Photo by Scott Massey.

Arch- A Passage Formed By A Curve (detail), 2020. Photo by Scott Massey.

Creative Output:

In addition to her visual art practice, Sandoval is also a published poet and essay writer.

Her literary work, like her art, delves into themes of land, place, and environmental stewardship from an indigenous-influenced perspective.

This dual commitment to both visual and written expression demonstrates Sandoval’s versatility as a creative practitioner.

References:

-https://www.chsandoval.com/home

-https://www.parraschheijnen.com/artists/christine-howard-sandoval

Jackie Amézquita

Jackie Amézquita (Quetzaltengo, Guatemala, b.1985) lives and works in Los Angeles, California. She is an artist with a multidisciplinary practice. Her research is articulated through the use of material and forms associated with pre-Columbian cultures. Amézquita creates public performances, installations, and objects that fuse indigenous mythologies with contemporary community engagement.

Amézquita received her M.F.A. from the University of California, Los Angeles, in 2022 and her B.F.A. from Art Center College of Design, Pasadena, CA, in 2018. She has exhibited with The Hammer Museum, LACE (Los Angeles Contemporary Exhibitions) CA, LAND (Los Angeles Nomadic Division) CA, 18th St Art Center CA, The Armory Center of the Arts CA, Vincent Price Art Museum CA, The Annenberg Space for Photography CA, Human Resources Los Angeles CA, MAD (Museum of Art and Design) NY. Amézquita is the recipient of the Mohn Public Recognition Award (2023), Mohn Land Award (2023), Andy Warhol Foundation for the Arts Los Angeles Art Fund (2022), and National Performance Network Fund (2022). Amézquita has been featured in the Los Angeles Times, ARTnews, and The Art Newspaper, LA. Weekly, hyperallergic, Walker Art Center magazine.

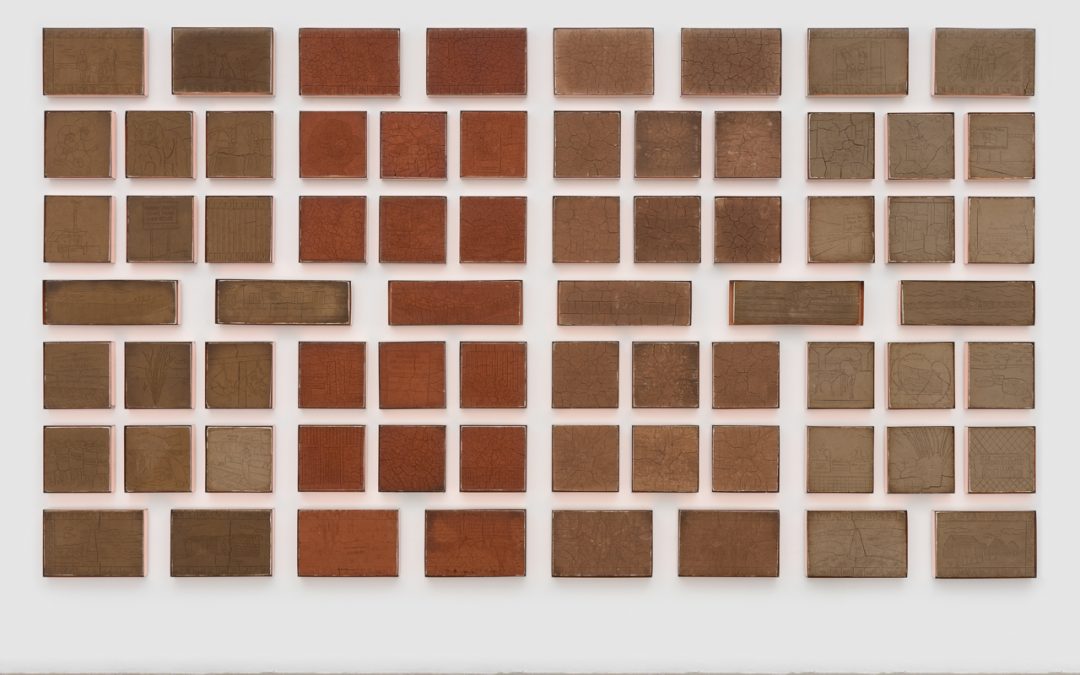

Works

SOIL

Soil source from the 1,951 mile border that connects the U.S and Mexico, corn masa, salt, cal (dehydrated lime), rain water, framed with copper.

Copper

Banana, salt incubated over a period of five months on copper

Fiber

Pasadena, California

Dimensions: 40’X40’

Sueños Fértiles, 2018 (Fertile Dreams) looks at the journey thousands of people make across different border entries into the United States. In this installation, I’m interested in the transformation that happens to a body upon entering a new space, as well as the effect of this interaction on the space. This exhibition is the next evolutionary stage of my previous installation, Mi Ultimo Suspiro, 2017 (My Last Breath). In Sueños Fértiles, I reconnect the remains of the clothing and towels that soaked all the water from the previous installation by casting them with salt, forming crystallized bundles of memories.

Door/Loom: Construction wood, screws, nails, woven clothing from people that migrated from different parts of the world, fiber crochet chains, 100% American soil, 45% traveled 150 miles South West of Pasadena, 5% traveled 140 miles south of Pasadena, 45% traveled 5.1 miles west of Pasadena, and 5% traveled 2.5 miles east of Pasadena (The soil was transported in the home depot buckets), acquired clothes from the different border that connects the US and Mexico, laundry detergent and salt (Crystals were formed inside the home depot buckets), 100 % Latin American string, Home Depot rags and towels from Mi Ultimo Suspiro.

Dimensions variable

In Between Borders, 2017 is a silkscreen of three photographs taken in 2016 of the border of Ramallah in Palestine, the US border of San Ysidro, CA, and Tijuana, BC, Mexico, and a window in Jerusalem, Israel.

Public works

A collaborative performance during AMBOS Project with Tanya Agüiñiga.

Douglas, Arizona-US, and Agua Prieta, Sonora-Mexico

Backstrap weaving is a time-honored technique that requires a long, narrow loom wrapped around the waist of the weaver and secured to a stationary object. In tension, Tanya Aguiñiga and Jackie Amézquita’s bodies serve as stationary as both the body and the stationary object weave from one side to the other side of the border fence. Agüiniga and Amézquita received training in back strap weaving from Mayan women in Chiapas and Guatemala, respectively. Aguiñiga is a staunch advocate for honoring pre-colonial cultures and knowledge through the art of backstrap weaving while also maintaining a strong connection to physical labor. Meanwhile, Amézquita sees weaving as a way of reconnecting to one’s cultural identity and ancestral knowledge.

The border fence united the two artists during an activation at the border. Aguiñiga was stationed in Douglas, Arizona, while Amézquita was in Agua Prieta, Sonora, Mexico, in full view of the US Border Patrol. This location holds immense significance for Amézquita, who attempted to enter the US undocumented as a teenager to reunite with her mother in 2003.

Nakbe, El Mirador, Petén Guatemala Photos by Rony Rodriguez

It’s an activation in Nakbe, approximately 13 kilometers south of El Mirador in Guatemala. Nakbe is one of the oldest cities in the region currently occupied by Petén Itzá. Archaeological excavations in the area suggest that the city is from the formative period or pre-classic 1400 BC. It’s believed that the city collapsed in 100-200 AD. Amézquita thinks of soil as an archive that holds the memory of the past. During this activation, the environment witnessed the integration between human and nonhuman entities. The actions of Amézquitas’s body in space serve as a conduit of reconnection between the past, the present, and the future. The feathers on her head were found during the journey, acknowledging the animal entities that inhabit the place.

Attending to the wound: a wake, a waiting, a witnessing 2023

Attending to the wound: a wake, a waiting, a witnessing 2023

Performance with LaRissa Rogers 23:49 min

Documentation provided by LACE, edited by Vladimir Santos.

attending to the wound: a wake, a waiting, a witnessing is a performance activating a collaborative installation of Hieroglyphs of metaphysical lacerations, drawing from previous works A Poetic of Living 2019 by LaRissa Rogers and Sueños Fértilez 2,018 by artist Jackie Amézquita. Using Black Care by Calvin Warren as a point of departure, the performance starts at sunset and works through grief, solidarity, and weight transfer. The performance addresses the five stages of grief: denial, anger, bargaining, depression, and acceptance.

References

– https://hammer.ucla.edu/made-la-2023-acts-living/jackie-amezquita

– https://jackieamezquita.com/

Andy Goldsworthy

The artist Andy Goldsworthy in “Leaning Into the Wind.” Credit:Thomas Riedelscheimer/Magnolia Pictures

Andy Goldsworthy is an international based artist born in England. His art process is known for integrating and creating with the natural environment. Working as both sculptor and photographer, Goldsworthy crafts his installations out of rocks, ice, leaves, or branches, cognizant that the landscape will change, then carefully documents the ephemeral collaborations with nature through photography.

Andy Goldsworthy, “Tree Fall“, 2013

Goldsworthy has numerous art installation and creations. However, his art installation, Earth Wall, utilizes rammed earth and eucalyptus branches to illustrate simulated layers of earthen materials as an art form and not as a structural material.

Andy Goldsworthy, Earth Wall, 2014, Photograph by The Chronicle’s Sam Whiting.

Andy Goldsworthy, Earth Wall, 2014, Photograph by The Chronicle’s Sam Whiting.

In order to construct this installation Goldsworthy and his team collected curved eucalyptus branches from San Francisco’s Presidio. Then they installed a sphere of branches onto a wall before the formwork for the rammed earth wall is installed.

After which, a shutter formwork was constructed in front of the wall. Then locally sourced Presidio earth mixed is poured into the forms, and ramming begins. Rammers carefully compact earth around the twisted ball of Eucalyptus branches. Once poured, the formwork is removed revealing a freshly packed rammed earth wall and the center point of the ball of gnarled eucalyptus branches.

Once hardened, Goldsworthy excavates the rammed earth from around the gnarled eucalyptus wood.

For a more detailed visualization view this video.

Andy Goldsworthy continues exploring the relationship between art and the natural environment. His ability to become attuned to his environment mentally, physically, and emotionally, creates a unique perspective of the human and natural world.

“We often forget that WE ARE NATURE. Nature is not something separate from us. So when we say that we have lost our connection to nature, we’ve lost our connection to ourselves.”

– Andy Goldsworthy

Andy Goldsworthy, “Wood Line“, 2011, Photograph by Brian Vahey.

References:

- Rammed Earth Works

- Andy Goldsworthy’s Earth Wall

- Goldsworthy in the Presidio

- Andy Goldsworthy in the Presidio

Dineo Seshee Bopape

Dineo Seshee Bopape is a South African contemporary artist known for her multimedia installations, video art, sculptures, and performances, in which she incorporates organic materials like soil (EARTH), coal, ash, and clay. Her environmental installations delve into themes of memory, identity, and belonging, pushing visitors to experience soil in a completely different way.

Bopape’s art draws heavily on African cosmologies, oral histories, and indigenous knowledge systems, addressing the complexities of belonging and displacement. Born in Polokwane, South Africa, the artist takes from her own experience and weaves narratives that investigate archetypes and myths in which the female figure plays a central role.

Bopape’s art draws heavily on African cosmologies, oral histories, and indigenous knowledge systems, addressing the complexities of belonging and displacement. Born in Polokwane, South Africa, the artist takes from her own experience and weaves narratives that investigate archetypes and myths in which the female figure plays a central role.

Her practice reflects on the body, emotions, trauma, and the unseen or spiritual dimensions of life. Her installations evoke layered meanings and leave room for ambiguity. Viewers must therefore engage with both material and metaphor.

With memory, belonging, and place.

Her installations have been featured all around the world, making it toPirelli HangarBicocca’s gallery in Milan, Italy with Born in the first light of the morning [moswara’marapo].

This exposition asks the question: What Memories are preserved in Stones, Water, and Earth?

This exposition asks the question: What Memories are preserved in Stones, Water, and Earth?

Here, historical and geographical references are brought together, to reflect on the memory, and more specifically the transmission of memory through natural elements like water and earth, and the use of sounds and words as healing. The installation draws on the symbolic use of earth, organic elements, and rituals, alluding to ancestral connections, healing practices, and African cosmologies. “Moswara’marapo” translates from Sesotho to “the smell of bones,” which adds a layer of meaning to the work, suggesting ideas of mortality, memory embedded in the earth, and the cycles of life and death.

“Born in the first light of the morning [moswara’marapo]” is just one example of the ways Dineo Seshee Bopape translates memory, spirituality, and materiality into powerful artistic experiences. But her work extends far beyond this single installation. From “Untitled (Of Occult Instability) [Feelings]” to “More/Moreana,” Bopape’s art challenges us to engage deeply with themes of identity, healing, and historical trauma.

Her use of natural elements like soil, water, and ash does more than reflect the material world—it urges us to question our relationship with these elements. Her work invites us to consider how land and memory are intertwined and how ancestral knowledge persists within the earth and within us. Through her installations, Bopape reminds us that nature is not just a backdrop to human experience but a living archive that holds our histories, traumas, and hopes for transformation.

Her use of natural elements like soil, water, and ash does more than reflect the material world—it urges us to question our relationship with these elements. Her work invites us to consider how land and memory are intertwined and how ancestral knowledge persists within the earth and within us. Through her installations, Bopape reminds us that nature is not just a backdrop to human experience but a living archive that holds our histories, traumas, and hopes for transformation.

References

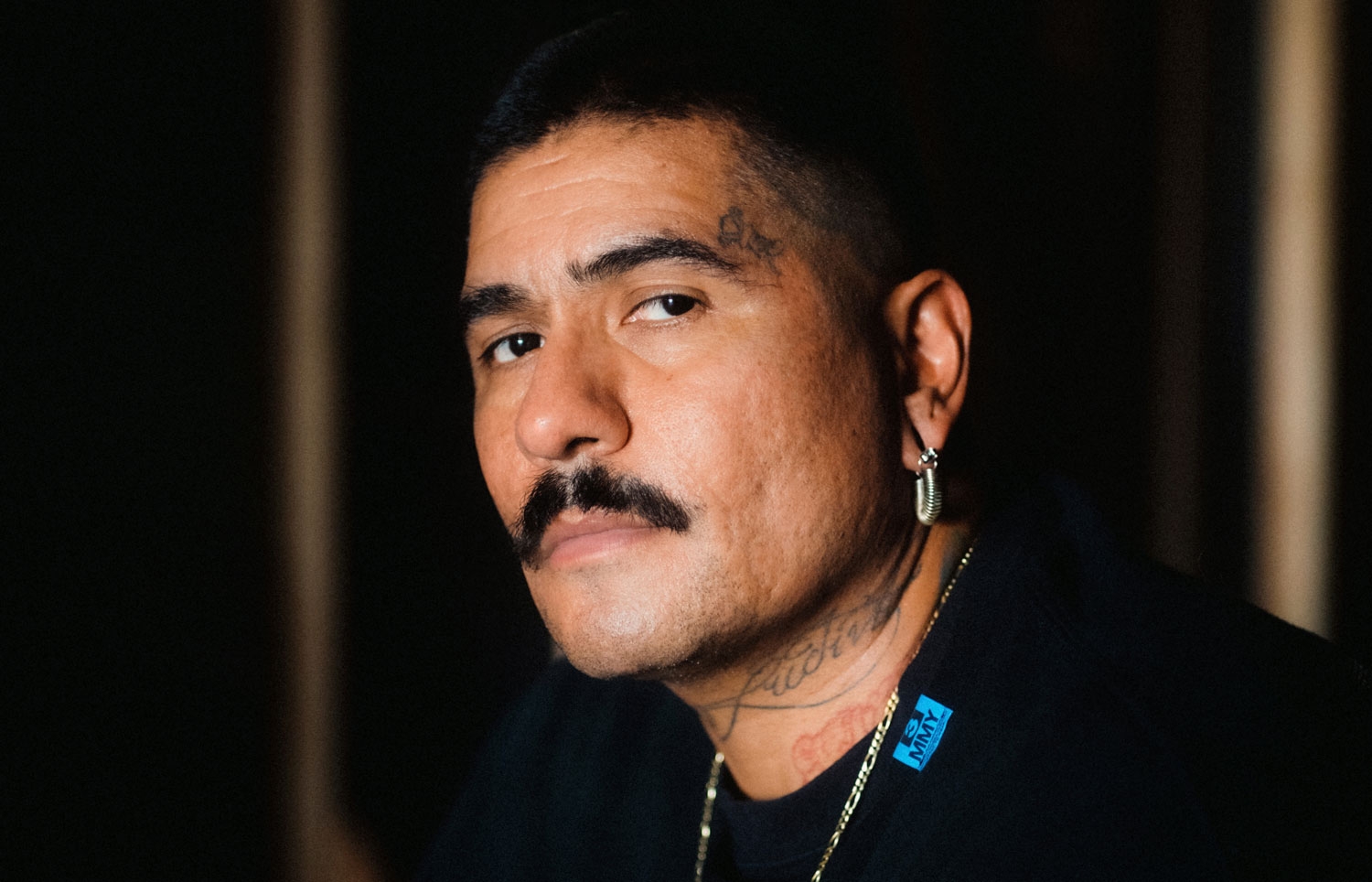

Rafa Esparza

Rafa Esparza is a Los Angeles-based multidisciplinary artist, known for exploring the intersections of history, identity, and place through his work. Born and raised in East L.A., Esparza draws inspiration from his Mexican-American culture. His installations, performances, and sculptures delve into themes of colonization, queer identity, and environmental concerns, critiquing ideologies, power structures and binaries. Esparza frequently collaborates with other artists and his community, including his family members.

His most prominent works consists of building adobe structures in unconventional spaces, such as the Los Angeles River and art galleries. This in reference to both his familial roots and indigenous building traditions they also emphasize the labor and traditional skills involved.

“I just knew that adobe had a special place in his own personal history, and I thought it could be a good way to start having conversations about some guidance that I needed at the time as a young person coming into adulthood. What it did, in fact, was allow us to share space without being at each other’s necks, while he passed down this way of working with land”

Rafa Esparza, on mending his relationship with his father through earth

Esparza challenges institutional frameworks and addresses socio-political issues (e.g. immigration, race, and marginalization). His work, at its core, is about storytelling and resistance, using art as a platform to engage with broader discussions on identity and systemic injustice.

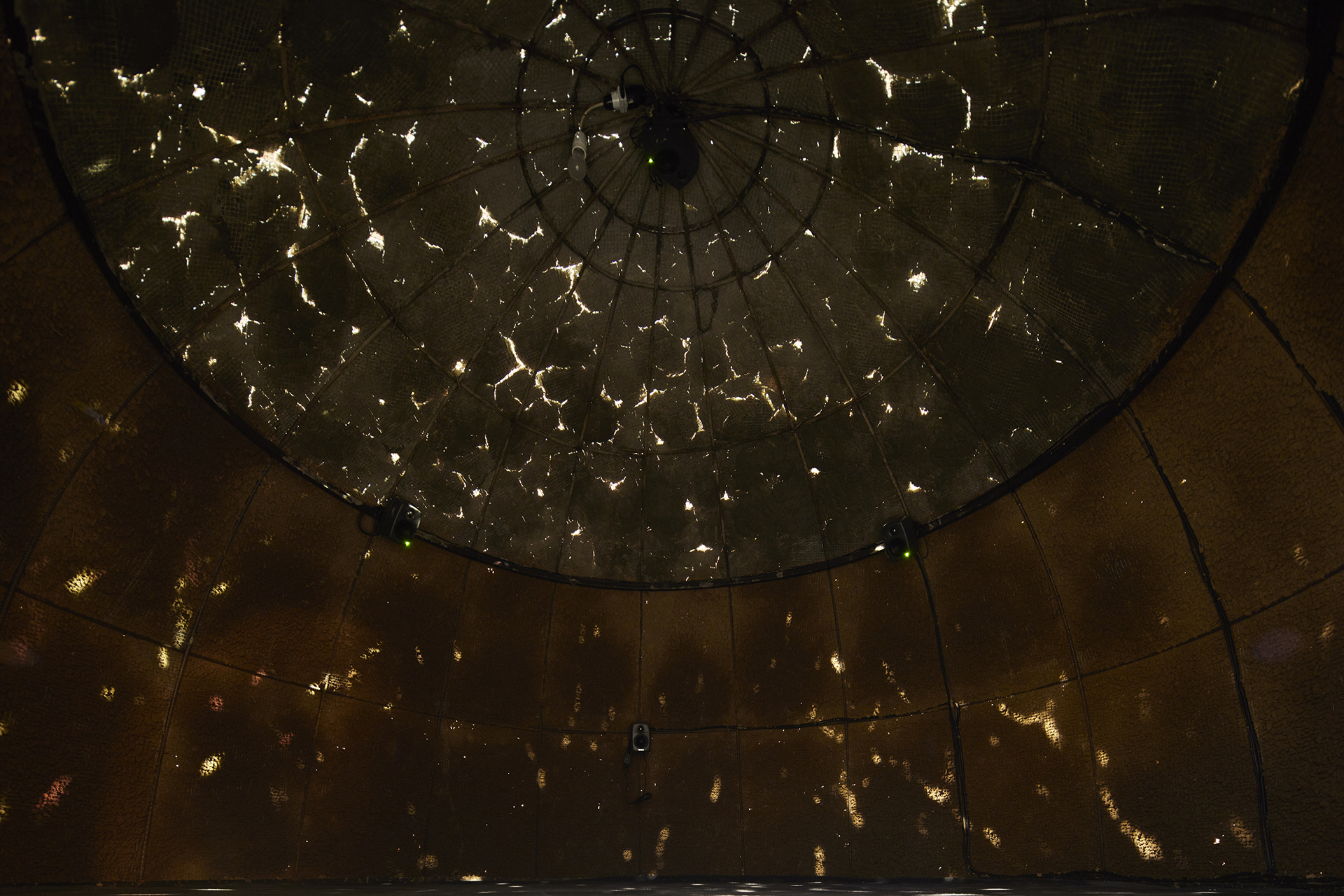

In Whitney’s 2017 Biennial, in New York City, Rafa Esparza’s Figure/Ground: Beyond the White Field, created an immersive microclimate. What was once, a white cubed gallery is covered in what Esparza calls “brown matter,” adobes; a mixture of hay, clay, horse dung, and water from the LA River, baked under California sun, and transported across U.S. coast’s. By invitation fellow queer artists to become adoberos, and helped to collectively created nearly five thousand adobes for the installation.

“Brown matter” or adobe is used not only in reference to skin color, but also a broad range of conversations on race, nationality, ethnicity, and gender and the intersections therein. Most especially, concerns surrounding the 2016 U.S. Presidential election of Trump.

To complete the installation, five other artists were invited to exhibit their mixed-media artwork within the adobe rotunda. The adobe rotunda plays is both an artwork itself and a space for exhibiting the work of others (figure and ground).

References

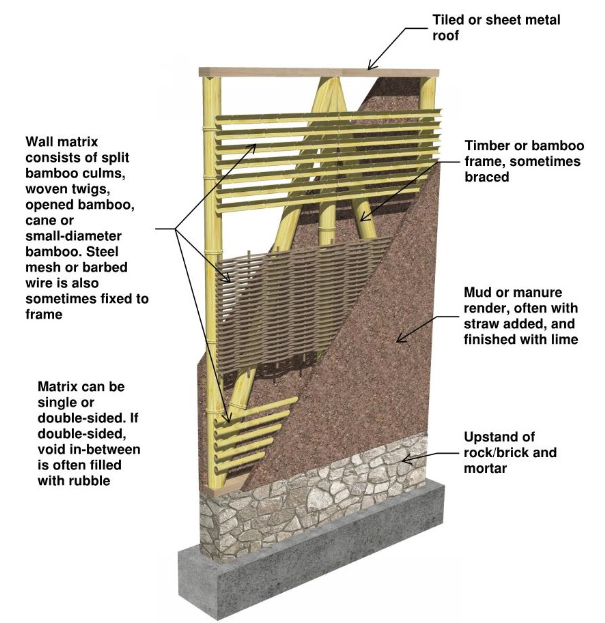

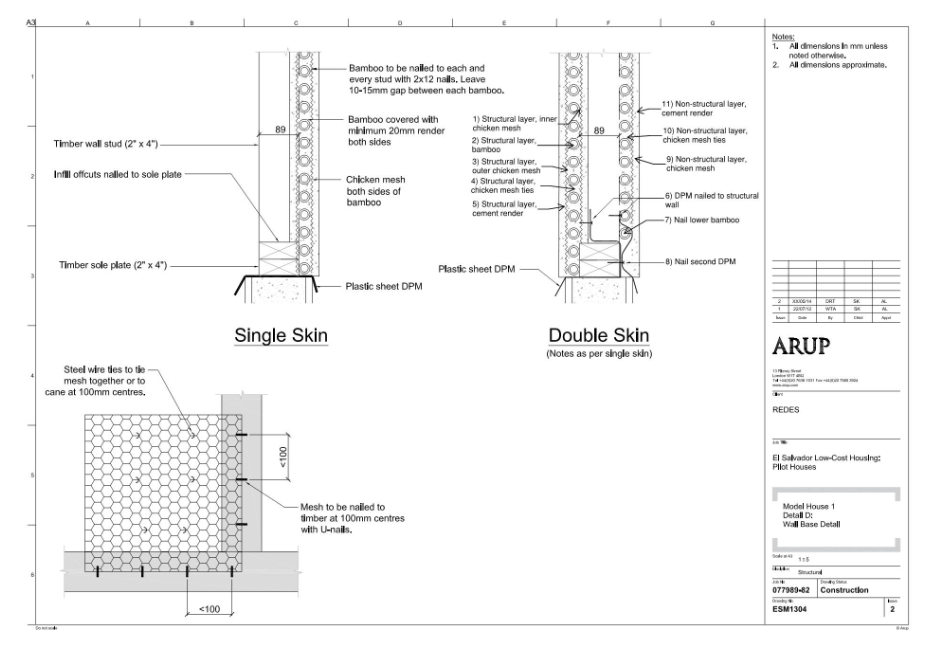

Bahareque (alternatively spelled bareque, also known as quincha)

Bahareque is the Spanish name for what is known in English as wattle and daub, a method of building where wet loam is applied to an interwoven mesh of twigs, branches, bamboo, etc. Specifically, bahareque (also known as quincha) is a subset of the thrown loam technique, where the wet loam is applied by hand onto the organic skeleton. The loam of earth (a combination of clay, silt, and soil) and aggregate, usually straw. Bahareque describes a wide range of building techniques and types, and can be separated out into various local traditions across South America.

Originally combined with palm frond roofs, bahareque was often topped with tiled roofs after European colonization. It can be used in combination with other earthen architecture technologies, as seen in the image below.

Bahareque is currently being explored as a low-cost housing typology. There are questions as to how well it can withstand seismic activity, but it is often proposed as a housing solution for earthquake stricken regions. Costa Rica, Ecuador, and Brazil have all introduced engineered bahareque (or cement bahareque) following devastating earthquakes.

In Ecuador, where the matrix and frame for bahareque architecture is made of guadua bamboo, one of the strongest bamboo subspecies, there is promising contemporary research proving that bahareque is superior to masonry architecture both for earthquake safety and from a sustainability standpoint.

References:

[1] http://www.crockerltd.net/adobe_big_one.htm

[2] https://www.seismico.org/bahareque

[3] https://www.researchgate.net/publication/282701710_Engineered_bamboo_houses_for_low-income_communities_in_Latin_America

[4] https://www.researchgate.net/publication/311583390_Design_Guide_for_Engineered_Bahareque_Housing/download

Munarq: Ca na Pua an Earthen Oasis

Image Source: Munarq

Image Source: Munarq

Project Start : 2021

Project End : 2024

Location : Binissalem, Mallorca, Spain.

Team : Munarq Architects

Gross Floor Area: 300 m²

Ca na Pua is a sustainable earthen home built in Binissalem, Mallorca; an island off the shore of Spain’s Mediterranean Sea. Ca na Pua was designed by munarq, an architectural studio based in Mallorca founded by Rafel Munar and Pau Munar focused on the integration of architecture in the Mediterranean landscape. inclusion of the environment

To construct this house munarq used an old local Mallorcan technique known as ballast. During this process, aggregates of various sizes, stone, and lime are mixed together to create a strong base. Then an open diffusion membrane between two ballast to allow for waterproofing. Waterproofing supports the overall longevity of the building while maintaining a healthy indoor environment.

The interior of the house uses a coat of earth and lime that creates hygrothermal environment environment. The earth-lime mixture acts as a natural buffer, absorbing and releasing moisture to maintain a comfortable and stable indoor climate.

The roof is insulated using straw coverage laced between laminated wood beams. This setup creates a dense and well-integrated insulation layer that provides thermal resistance.

There is an interaction with the built environment with the build patio or oasis shared within the home.

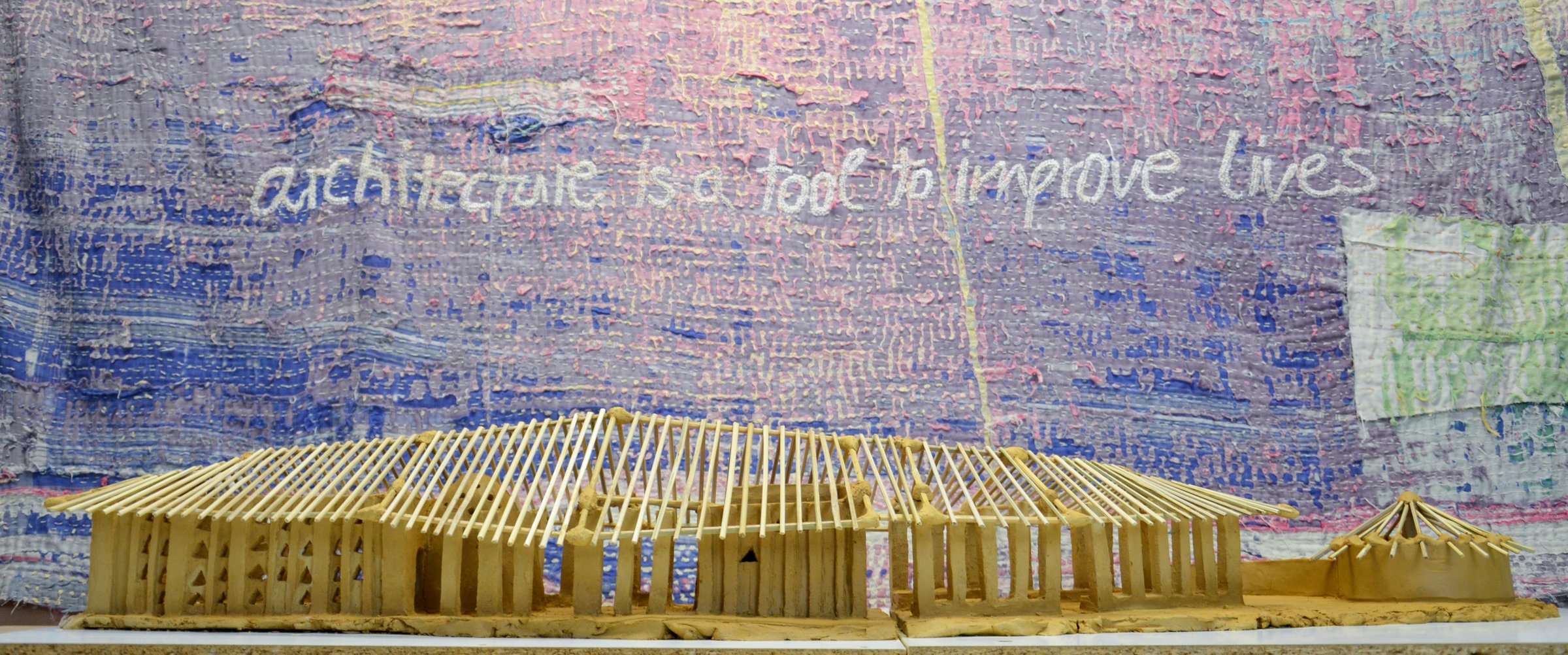

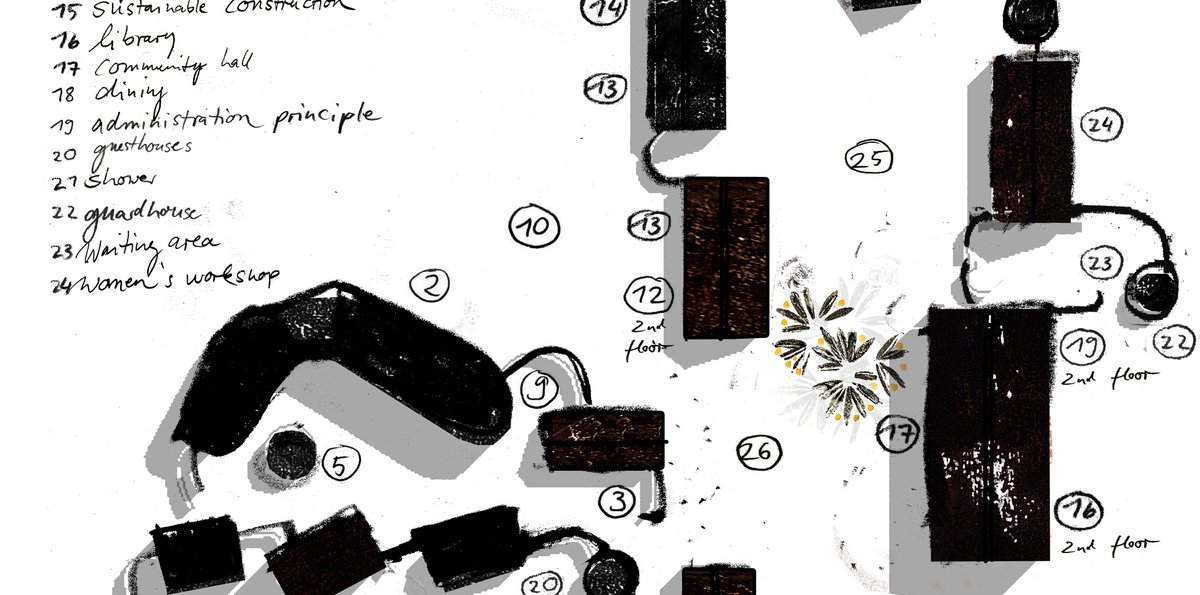

Anna Heringer: Earth Campus

The Earth Campus in Tatale, Ghana, is a vocational training center designed to promote sustainable development through education and practical skill-building in one of Ghana’s rural regions, close to the Togo border. The project focuses on providing young people with the skills needed to support their families and counteract rural exodus. It is operated by the Salesians with the Don Bosco mission, which aims to empower the local community through sustainable techniques and education.

The Earth Campus in Tatale, Ghana, is a vocational training center designed to promote sustainable development through education and practical skill-building in one of Ghana’s rural regions, close to the Togo border. The project focuses on providing young people with the skills needed to support their families and counteract rural exodus. It is operated by the Salesians with the Don Bosco mission, which aims to empower the local community through sustainable techniques and education.

The campus offers training in sustainable construction methods such as adobe masonry, rammed earth, and timber structures. It also includes programs in agriculture, electrical training, domestic economy, and nutrition, giving students a broad range of skills. The campus is designed to incorporate local building traditions while teaching modern adaptations of these methods, blending vernacular architecture with contemporary sustainable techniques.

The use of local, natural materials such as earth plays a crucial role in reducing environmental impact while creating economic opportunities for the community. The project also uses natural ventilation strategies, ensuring comfort in the hot and humid climate of the region. The overall goal is to make the campus a model for how development projects can foster both environmental sustainability and social empowerment by maximizing local resources.

Through its design, the Earth Campus serves as an example of how architecture can be a tool for development. It challenges the conventional approach of using industrialized, imported materials in aid projects and demonstrates the benefits of building with locally available resources. This ensures that the added value remains within the community, fostering long-term sustainability and cultural preservation.

About the architect:

Anna Heringer is a renowned architect from Germany. She studied at the University of Art and Industrial Design Linz in Austria, focusing on sustainable architecture using local materials and techniques. Her work is rooted in creating environmentally and socially responsible architecture.

Heringer’s philosophy centers on sustainability and empowering communities through architecture. She emphasizes the use of natural, local materials, aiming to create socially and ecologically responsible structures. Her projects often focus on education, community development, and uplifting marginalized regions, particularly through vocational training and local engagement.

Anna Heringer runs her architectural practice, Studio Anna Heringer, with projects across the globe, including in Bangladesh, Ghana, and Europe. Her designs are grounded in cultural sensitivity and sustainable practices that challenge conventional construction norms.

Citations:

- Anna Heringer, “Tatale Earth Campus Project,” Anna Heringer Official Website, accessed October 15, 2024, https://www.anna-heringer.com/projects/vocational-school-tatale-ghana.

- Architecture for Hope, “Earth Campus Overview,” Architecture for Hope, accessed October 15, 2024, https://architectureforhope.com/work/earth-campus.html.

- Transsolar, “Tatale Educational Campus Project,” Transsolar KlimaEngineering, accessed October 15, 2024, https://transsolar.com/projects/tatale-educational-campus.

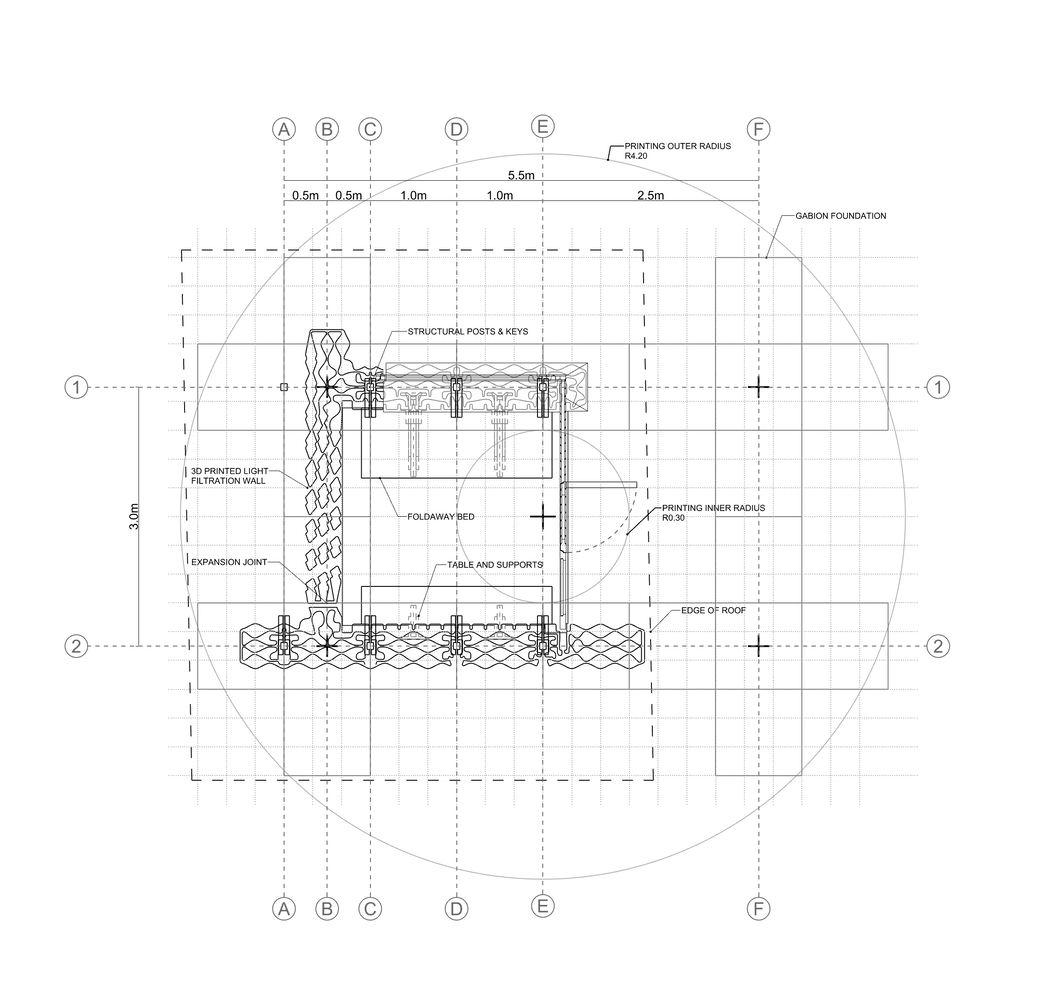

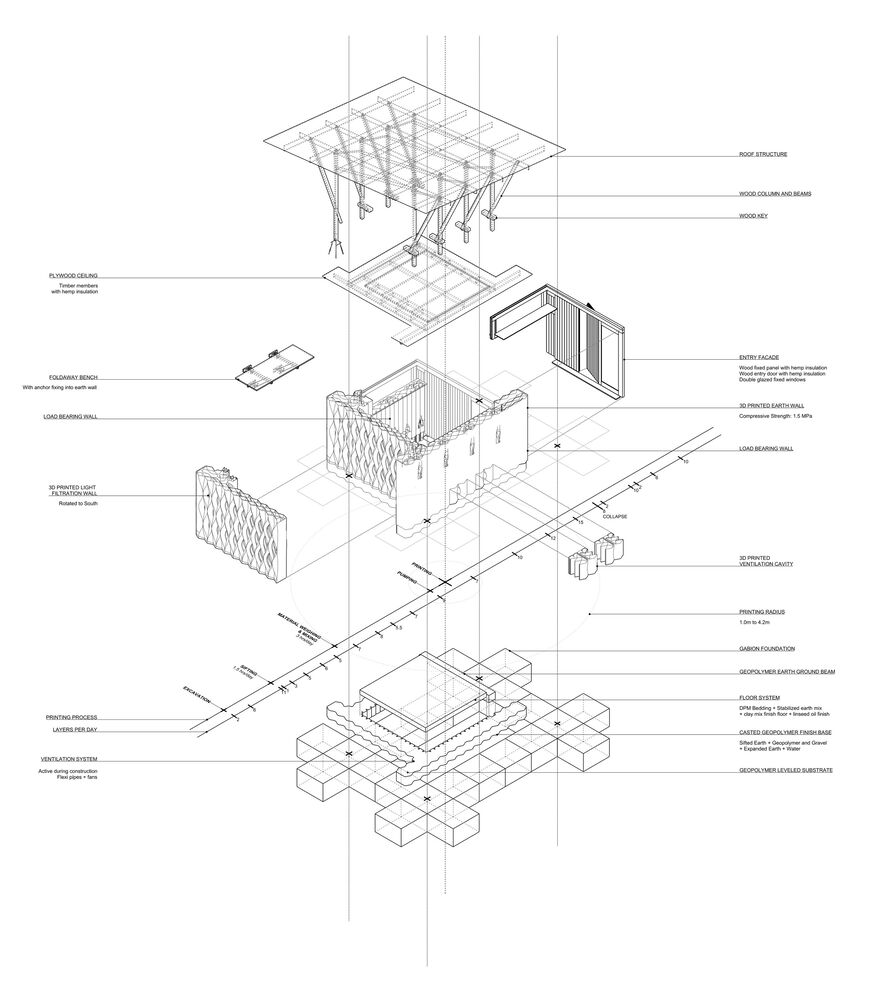

IAAC: TOVA

TOVA is the first architectural construction in Spain located in the facilities of IAAC Valldaura Labs, Barcelona, built with a Crane WASP, the architectural 3D printer. The project was completed in 2022. The construction can be completed within weeks using 100% local materials and local labor, zero waste and a close to virtually zero carbon emission footprint. This manufacturing system can be used anywhere in the world and can help to housing emergencies. The project has been developed by the team of students and researchers from the 3D Printing Architecture (3dPA) postgraduate program of the Institute for Advanced Architecture of Catalonia (IAAC).

Also, this project is one of the most sustainable and environmentally friendly construction forms that can be applied today. The construction took 7 weeks time to complete, a Crane WASP, the architectural 3D printer and km zero materials. The structure is made ofclay and water obtained on site. To ensure the longevity of the material in resistance to weather, a waterproof coating is added using raw extracted materials such as aloe and egg whites.

Thebuild area is 9 m2. The prototype took into account performative design strategies, conceived during a two-week design charette where students synthesized the lessons learned in the research phase to develop the components of the prototype: light openings, air flow, wall cavity ventilation, thermal conductivity, roof structure, built-in furniture, waterproofing and floor substructure.

The proposed design has different structural considerations in the roof beam system as well as the innate structure of the clay walls. The walls are designed to be braced with T and L joints, rather than straight lines. The resulting closed interior space is habitable, weather resistant and climatically adapted by the various design interventions.

Citation

https://iaac.net/project/3dpa-prototype-2022/

https://www.archdaily.com/988078/prototype-tova-posgrado-3d-printing-architecture-iaac