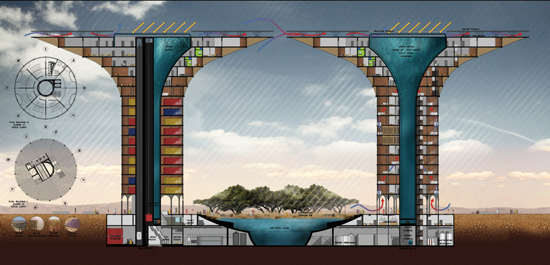

In a small shed on an industrial park near Pisa is a machine that can print buildings. The machine itself looks like a prototype for the automotive industry. Four columns independently support a frame with a single armature on it. Driven by CAD software installed on a dust-covered computer terminal, the armature moves just millimetres above a pile of sand, expressing a magnesium-based solution from hundreds of nozzles on its lower side. It makes four passes. The layer dries and Enrico Dini recalibrates the armature frame. The system deposits the sand and then inorganic binding ink. The exercise is repeated. The millennia-long process of laying down sedimentary rock is accelerated into a day. A building emerges.

The new material (inorganic binder + sand or mineral dust) has been subjected to traction, compression and bending tests. The results have been extraordinary and the artificial sandstone features excellent resistance properties. Effectively this process returns any type of sand or mineral dust back to its original compact stone state.

The binder transforms any kind of sand or marble dust into a stone-like material (i.e. a mineral with microcrystalline characteristics) with a resistance and traction superior to portland cement, to a point where there is no need to use iron to reinforce the structure. This artificial stone is chemically one hundred percent environmentally friendly.

The process is four times faster than conventional building, costs a third to a half as much as using Portland cement, creates little waste and is better for the environment. But its chief selling point may simply be that it makes creating Gaudiesque, curvy structures simple.

Read more at [ Blueprint Magazine | Dezeen | Previously ]